Quality Control

At Birdağ Makina, we implement stringent quality control measures at every stage, from raw material entry to final product delivery. We utilize the latest measurement and control technologies to ensure customer satisfaction throughout our production processes.

Key devices used in our quality control processes include:

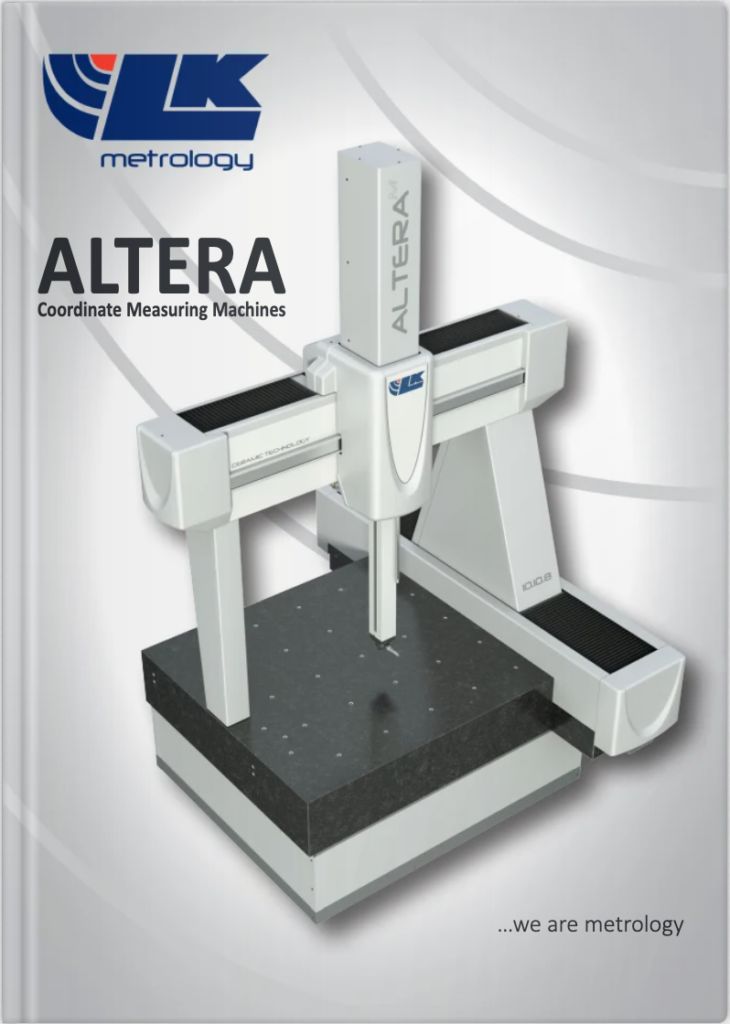

CMM (Coordinate Measuring Machine): To guarantee precision in our manufacturing process, we employ a CMM device:

NIKON LK ALTERA 10.7.6

Profile Projector: For precise measurement of component profiles, we use a profile projector:

NIKON V12B

Manual Measuring Instruments: To maintain quality throughout our production processes, we also utilize various manual measuring instruments:

Micrometer

Caliper

Gauge Blocks

Depth Gauge

All these devices are operated in controlled environments and are continuously calibrated and monitored. Our quality control process ensures that our products are manufactured to high standards and meet customer expectations.

At Birdağ Makina, we are committed to maintaining the highest levels of quality. We meticulously work through every stage of production and continually strive for excellence by constantly improving our processes.

.